Clean. Safe. Simple.

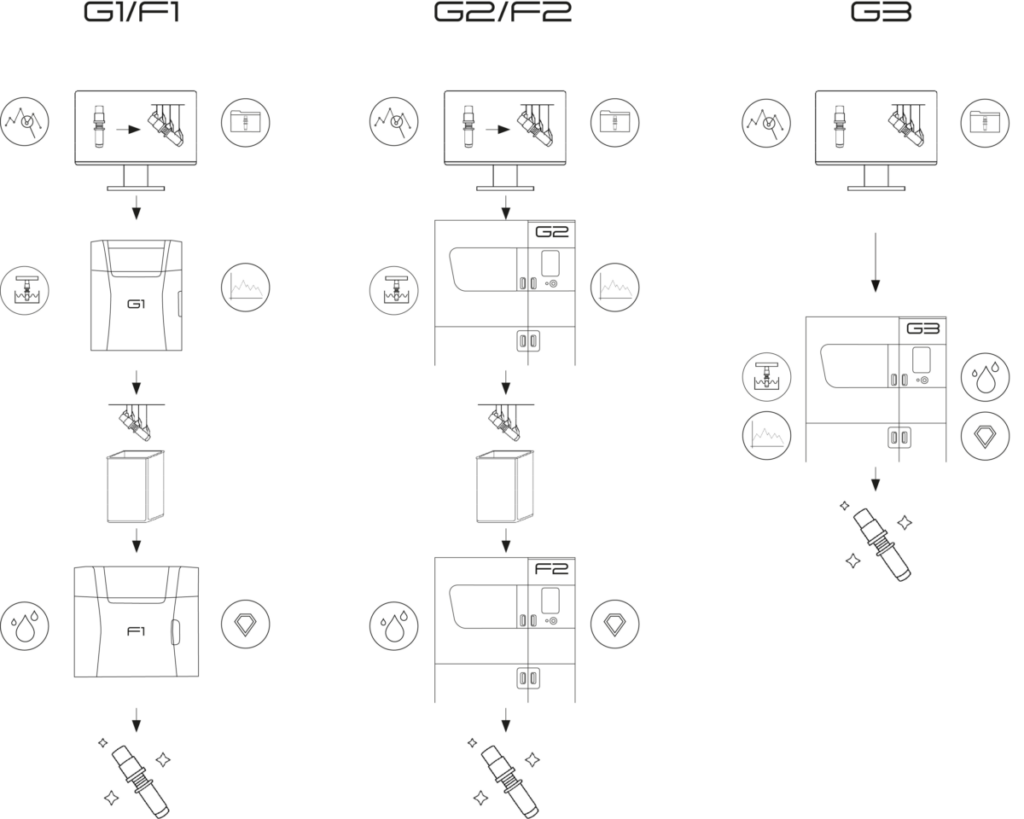

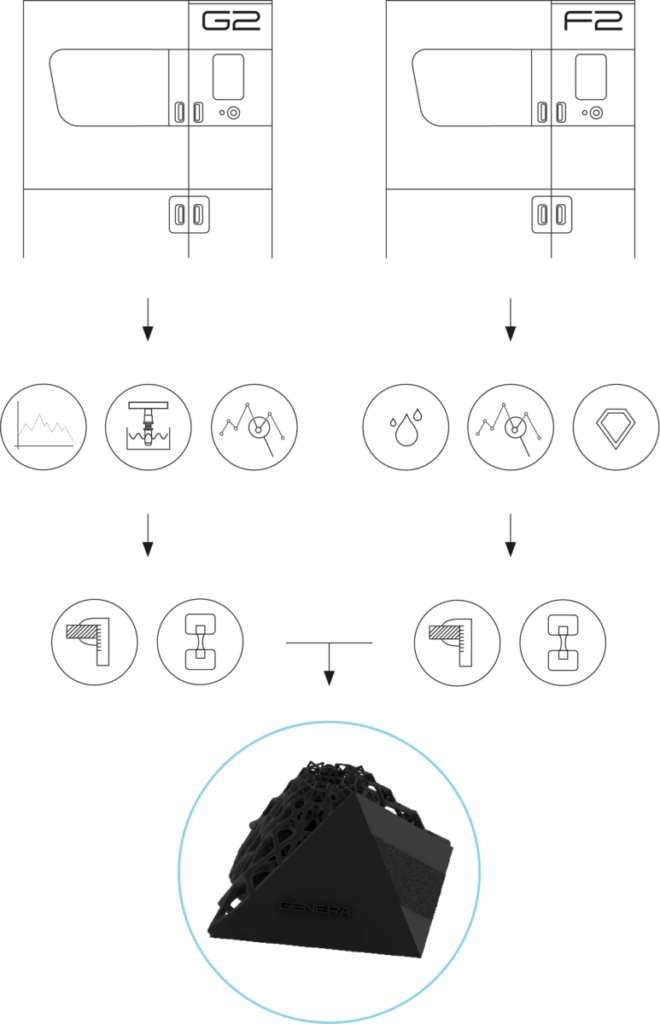

We offer our customers a workflow which is clean, safe and simple. All our systems are based on the idea to use such a workflow and a high degree of automation to enable real production with 3D printing. The G1/F1 process and the G2/F2 process use a glove-free handling system that is based on an innovative shuttle solution. During the entire production process, the printed part travels in a tight box or shuttle. Both the precious printed components and your hands are protected by this design. The printed component can be handled and processed without any dripping, contamination or light influence from outside. At the same time, the shuttle works as an interface between the 3D printer and the F1 or F2 post-processing unit. It documents the entire manufacturing process and makes it traceable and repeatable. The G3 offers an All-in-One solution, meaning the entire GENERA workflow is handled within the G3 itself. This includes printing the green part, washing and postcuring. All manufacturing data is documented and stored in the GENERA CAM.

G1 F1

G1 F1 G2

G2 F2

F2 G3

G3 A2

A2